Executive Summary: AI-Powered Safety Transformation

In high-risk industrial environments, manual safety monitoring fails to keep pace with fast-moving operations.

SafeVision AI delivers automated, real-time enforcement

that detects hazards instantly and generates audit-ready compliance documentation.

- Manufacturing

- Energy

- Oil & Gas

- Smart Facilities

- High-Risk Production

The Critical Safety Gap: Why Manual Monitoring Fails

The $4.2M Average Cost of Safety FailuresIndustrial operations face persistent challenges that outdated systems cannot address:

Manual Safety Systems

Limited Scope:

Human monitors can only observe 2-3 zones simultaneouslyDelayed Response:

Incidents detected 15-45 minutes after occurrenceIncomplete Data:

Heterogeneous sensor data remains unintegratedReactive Approach:

Investigations begin after incidents occurCompliance Gaps:

Manual documentation leads to audit failures

SafeVision AI Platform

Comprehensive Coverage:

AI processes 100+ video streams continuously across entire facilitiesReal-Time Detection:

Hazards identified in <800ms with instant automated alertsUnified Intelligence:

Video, thermal, and IoT sensor fusion with Delta LakeProactive Prevention:

AI predicts and prevents hazards before escalationAutomated Compliance:

Full audit trails with Unity Catalog governance

Industry Statistics

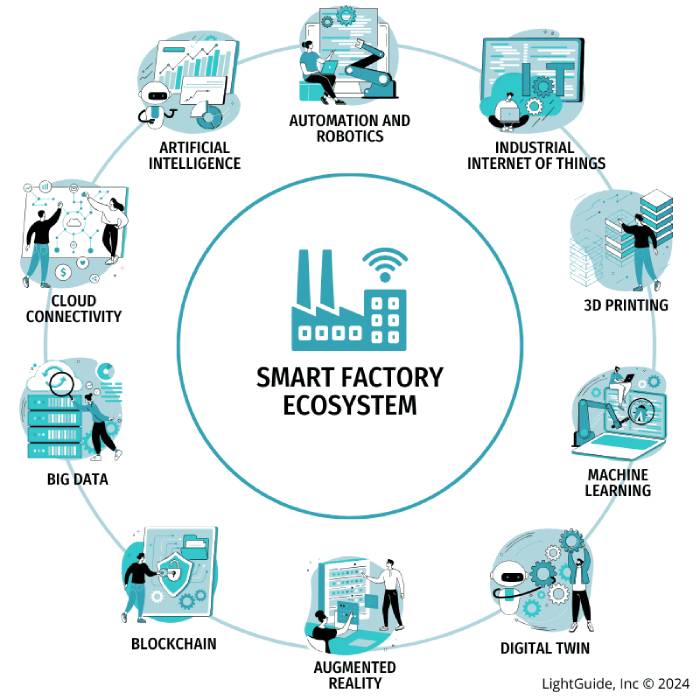

SafeVision AI Solution Architecture

Three-Phase Intelligent Safety PipelineBuilt on Databricks Data Intelligence Platform, SafeVision AI transforms raw sensor data into actionable safety intelligence:

Data Sources → Databricks Pipelines → Delta Lake Storage

- Video Streams (CCTV cameras, 1080p @ 15fps)

- Thermal Sensors (overheat detection)

- IoT Devices (equipment status)

- Access Control Systems (unauthorized entry)

Key Technology: Python StreamingEdge AI Delta Lake

Delta Lake → Mosaic AI → Computer Vision Models → Real-Time Inference

- PPE Compliance Detection (YOLO/OpenCV models, 99.1% accuracy)

- Fire & Overheat Risks (thermal pattern recognition)

- Unauthorized Access Detection (restricted zone monitoring)

- Unsafe Behaviour Identification (proximity, posture analysis)

Key Technology: YOLOOpenCV MLflow

Inference Results → Azure Functions → Multi-Channel Alerts → Safety Dashboard

- Immediate Alerts: Email/SMS/Teams notification in < 2 seconds

- Automated Logging: Incident records with full video evidence

- Compliance Documentation: Automated audit reports

- Safety Dashboard: Real-time visualization of all safety metrics

Key Technology: Azure Logic AppsDatabricks Model Serving

Technical Architecture: Databricks-Native Safety Platform

Core Platform Components

Heterogeneous Data Integration

Structured and unstructured data from cameras, thermal sensors, IoT devicesTime-Series Optimization:

Delta Engine accelerates frame analysis by 40x for real-time processingSchema Evolution:

Automatic adaptation to new sensor types and data formatsCompliance-Ready Storage:

ACID transactions ensure data integrity for audit requirements

-

Pre-trained Models

50+ specialized models for factory safety scenarios -

Fine-tuning Pipeline

Customize models for facility-specific requirements in <72 hours -

Active Learning

Models continuously improve with new incident data -

YOLO/OpenCV Integration

Optimized for high-speed, high-accuracy detection

-

Experiment Tracking

Compare 100+ model versions with performance metrics -

Model Registry

Stage, test, and deploy validated models with approval workflows -

Performance Monitoring

Automatic drift detection and retraining triggers -

Compliance Documentation

Full model lineage for regulatory requirements

-

Low Latency

<800ms end-to-end detection-to-alert pipeline -

Auto-scaling

Handle 1 to 1,000+ video streams without performance degradation -

Cost Optimization

Serverless inference with pay-per-use pricing -

Edge AI Integration

Hybrid deployment for latency-sensitive applications

-

Data Lineage

Full traceability from sensor input to safety decision -

Access Control

Role-based permissions for video data, models, and alerts -

Compliance Ready

Audit trails for OSHA, ISO 45001, and industry regulations -

Security Framework

SOC 2 Type II compliant data handling

Key Use Cases: Manufacturing & Energy Focus

Manufacturing Sector Applications- Real-time monitoring of robotic cell perimeters

- Automatic equipment shutdown on human intrusion

- PPE compliance enforcement in hazardous areas

- Thermal camera integration for overheat detection

- Fire risk prediction through pattern recognition

- Automatic cooling system activation triggers

- Ergonomic risk detection through posture analysis

- Machine guarding compliance monitoring

- Fatigue detection through movement pattern analysis

- Smoking detection in restricted areas with 99.3% accuracy

- Hot work permit compliance monitoring

- Gas leak early warning through visual and sensor fusion

- Unauthorized access detection in restricted zones

- Equipment overheating prevention

- Emergency response team alerting systems

- Corrosion and leakage visual detection

- Environmental compliance monitoring

- Environmental compliance monitoring

Quantifiable Safety Improvements

| Metric |

Industry Average |

SafeVision AI Results |

Improvement |

|---|---|---|---|

|

Workplace Accidents |

Baseline | 47-67% reduction | ↓ 67% |

| Response Time | 15-45 minutes | <60 seconds | ↓ 98% |

| Compliance Audits | 80-120 hours | 85% automated | ↑ 400% efficiency |

|

Near-Miss Reporting |

57% unreported | 92% captured | ↑ 61% |

|

Insurance Premiums |

Standard rates | 15-25% reduction |

$150K-$500K savings |

Annual ROI Calculation

ROI Components:- Incident Cost Reduction: $2.8M (based on 67% fewer accidents)

- Compliance Efficiency: $420K (automated reporting)

- Insurance Savings: $280K (premium reductions)

- Productivity Gains: $950K (reduced downtime)

- Real-time dashboard with predictive risk scoring

- Automated regulatory reporting (OSHA 300 logs, ISO documentation)

- Trend analysis across facilities and time periods

- 30% reduction in production downtime from safety investigations

- Workforce analytics for targeted safety training

- Integration with existing MES and SCADA systems

- Data-driven insurance premium negotiations

- Quantifiable risk reduction metrics

- Automated audit trail generation

- Centralized sensor data management on Databricks

- Standardized AI/ML platform reducing technical debt

- Enterprise-grade security and governance framework

Technical Specifications & Integration

Core Platform

- Databricks Data Intelligence Platform 14.3+

- Unity Catalog–enabled workspace

- Delta Lake optimized for time-series data

- MLflow model registry configuration

- Minimum 50 Mbps per 10 cameras (1080p @ 15fps)

- Edge processing capabilities for latency-sensitive applications

- Secure VPN for remote facility connectivity

- Hot Tier: Recent video data (30 days) for real-time analysis

- Warm Tier: Processed metadata and incident records (90 days)

- Cold Tier: Archived video evidence (7+ years for compliance)

Primary Stack

- Python 3.9 for pipeline development

- Computer Vision: YOLOv8, OpenCV, custom CNN architectures

- Edge AI: NVIDIA Jetson/Tesla integration for low-latency processing

- Stream Processing: Structured Streaming with Delta Live Tables

- Sensor Integration: REST APIs, MQTT, OPC UA protocols

- Mosaic AI for model training and fine-tuning

- MLflow for experiment tracking and deployment

- Delta Lake for unified data storage

- Unity Catalog for governance and compliance

Implementation Framework: Production-Ready in 90 Days

Safety Process Evaluation

Current incident analysis and risk zone identification

Camera and sensor infrastructure assessment

Integration requirements with existing systems

Databricks Environment Setup

Unity Catalog configuration for video and sensor data governance

Delta Lake optimization for time-series video data

MLflow model registry initialization

Limited Scope Implementation

5–10 camera pilot in highest-risk zones

Pre-trained model customization for facility-specific needs

Alert integration with existing communication systems

Validation & Performance Tuning

Accuracy benchmarking (target: >98% detection rate)

Latency optimization for real-time response

User acceptance testing with safety teams

Full Facility Deployment

Additional camera and sensor integration

Department-specific model training and deployment

Multi-facility rollout with centralized management

Centre of Excellence Establishment

Admin training and certification programs

Continuous improvement framework implementation

ROI measurement and reporting dashboard deployment

Industrial AI Excellence

Differentiated Capabilities

Manufacturing & Energy Specialization

- 40+ production deployments in hazardous environments

- 250+ industry-trained safety scenarios

- SCADA, DCS, MES, and ERP integration expertise

Databricks Elite Partnership

- Databricks APJ Innovation Partner – 2025

- 175+ Databricks-certified engineers

- Mosaic AI & Delta Lake contributors

Full-Lifecycle AI Implementation

- Edge-to-cloud architecture design

- MLOps automation & observability

- Change management and adoption programs

Client Success Metrics

Global Automotive Manufacturer

- 67% reduction in hand injury incidents

- $2.8M annual cost savings

- ROI in 5.2 months

- 24/7 monitoring across 3 facilities

International Oil Refinery

- Zero recordable incidents in 14 months

- 92% automated compliance reporting

- 15% insurance premium reduction

- 200+ high-risk zones monitored