US manufacturers and global energy operators face mounting pressure to run safer plants, slash unplanned downtime, and do more with leaner teams. Industry leaders see data and AI as the clear path forward, but siloed OT systems, legacy historians, and fragmented analytics tools continue to hold them back across multi-site operations.

Bizmetric and Databricks are partnering to close this gap by bringing a unified Data Intelligence Platform and proven industrial AI accelerators to real plants, fields, and control rooms. Together, the teams help operations, engineering, and digital leaders move from disconnected pilots to production‑grade AI across manufacturing and energy enterprises.

The New Foundation: Databricks Lakehouse for OT and IT

Traditional industrial data platforms were never designed for today’s AI workloads. Data is trapped in multiple historians, SCADA systems, MES, ERP, and spreadsheets. Getting a single, trusted view of performance across plants, fleet,s or grids is often the biggest challenge.

The Databricks Lakehouse provides a simple but powerful foundation by combining data lake flexibility with data warehouse reliability. Delta Lake brings ACID transactions, time travel, and scalable storage to streaming sensor data and batch business data, while Unity Catalog gives central governance, lineage, and fine‑grained access control across OT and IT domains. This architecture makes it far easier to build trusted, reusable data products for maintenance, quality, safety, and energy optimization use cases.

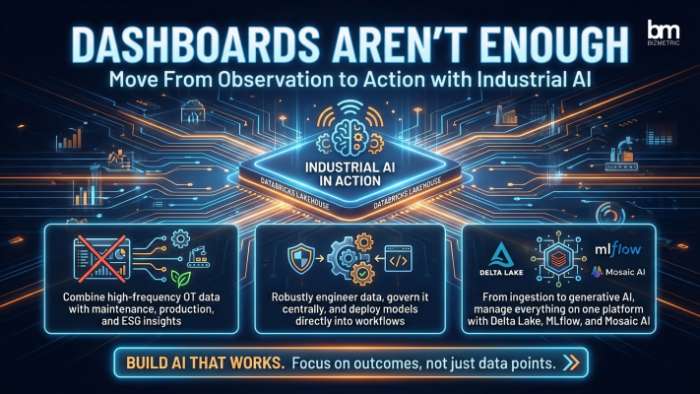

Why Industrial AI Needs More Than Dashboards

Most US manufacturers and global enterprises already have dashboards and reports in place, yet they still struggle to boost OEE, optimize energy usage, or predict failures with real confidence. The issue isn’t just technology—it’s the gap between raw data and the daily decisions operators and engineers need to make across plants and sites.

Industrial AI requires robust data engineering, strong governance, and the ability to operationalize models at scale. That means continuously ingesting high‑frequency OT data, combining it with maintenance, production, and ESG data, and then deploying machine learning and generative AI models back into workflows. With Databricks, this end‑to‑end lifecycle is managed on one platform using Delta Lake, MLflow, and Mosaic AI, so teams can focus on outcomes rather than plumbing.

Bizmetric Accelerators: SafeVisionAI, FlowAgent, and OT AI Platform

Bizmetric has packaged common patterns from real manufacturing and energy engagements into ready‑to‑deploy solution accelerators built on Databricks. These solutions help customers compress the time from idea to value and give Databricks field teams a concrete way to start conversations with industrial clients.

-

SafeVisionAI: Computer vision for safety and quality, using video data, Delta Lake and Mosaic AI to monitor PPE compliance, restricted zones and visual defects on lines or in yards.

-

FlowAgent: GenAI agents that act as “operations copilots”, helping technicians, planners and control room teams quickly access procedures, logs and work orders on top of a governed Lakehouse.

-

OT AI Platform: A repeatable industrial Lakehouse blueprint that unifies historians, SCADA, IoT and enterprise data to power predictive maintenance, energy efficiency and reliability analytics.

Real Outcomes for Manufacturers and Energy Companies

For US manufacturers and global operations, these solutions cut unplanned downtime, boost first-time-right quality, and build stronger safety cultures across plants and sites. Vision analytics and predictive models spot issues early—before they turn into costly incidents—while GenAI copilots walk technicians through troubleshooting in plain language.

For multinational energy companies with US refineries and global assets, the Databricks-powered OT AI Platform gives operators real-time visibility into production, pipelines, and grids. Blending sensor data with engineering, trading, and ESG insights unlocks throughput optimization, leak prevention, and compliance with tightening regulations worldwide.

A Trusted Partnership for Industrial Transformation

Bizmetric has been recognized as a leading Databricks partner in the region, bringing deep Lakehouse expertise and domain knowledge in manufacturing and energy. This experience matters when moving from workshops and prototypes to robust, governed solutions that fit existing OT and IT landscapes.

By aligning Databricks’ Data Intelligence Platform with Bizmetric’s industrial accelerators, customers get a clear, low‑risk path to scaling AI across plants, refineries and grids. The result is not a single project, but a repeatable way to re‑imagine how operations teams work with data and AI.

Conclusion

If you are exploring how to modernize industrial data and AI in your plants or energy assets, Bizmetric and Databricks can help you get started with a focused pilot that delivers measurable outcomes within weeks.

Get in touch to schedule an Industrial AI workshop tailored for your US manufacturing plants or global energy operations.

Write a Reply or Comment

You must Register or Login to add a comment.